Our advanced technology, including Laser Trackers and Handheld Scanners, empower industries with unparalleled capabilities in metrology, surveying, and 3D scanning. Whether you are optimizing manufacturing processes, ensuring quality control, or creating detailed 3D models, our team and equipment can deliver the precision you need.

The Technology:

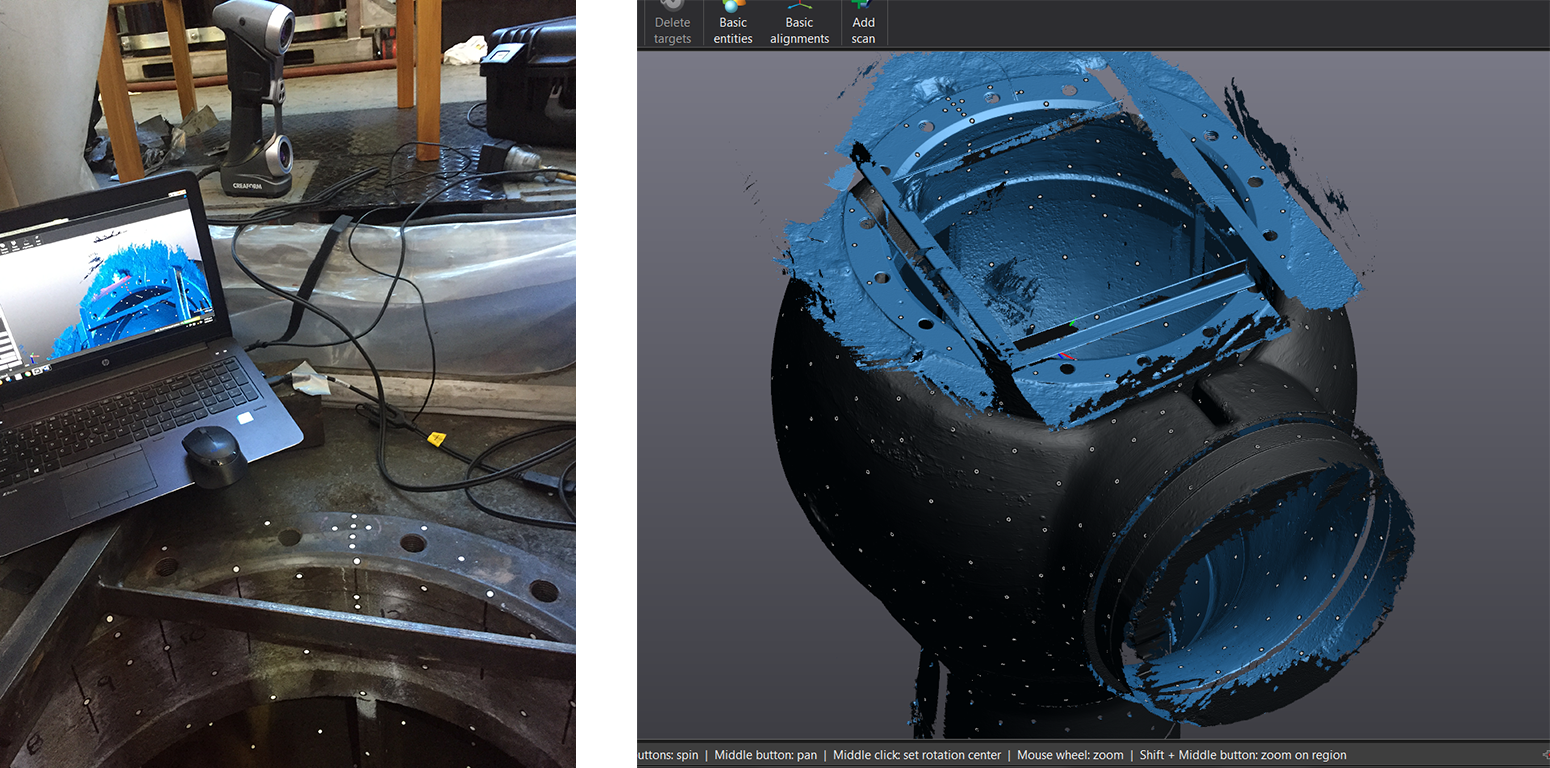

Creaform Handyscan 700

- Absolute point accuracy up to 30 µm (0.03mm)

- Volumetric accuracy 0.020 mm + 0.060 mm/m

- Ideally suited to scan parts that fit inside a 2 cubic metre volume

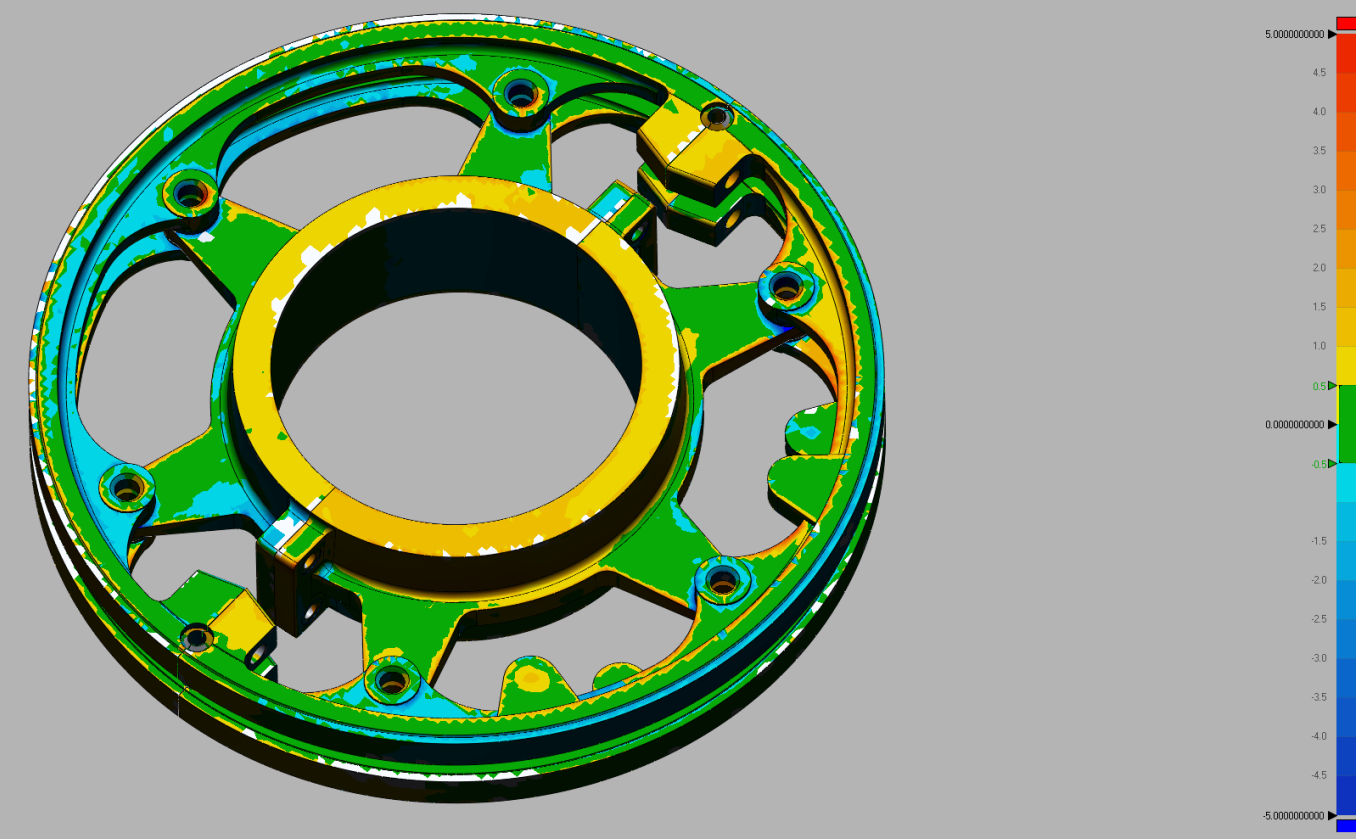

Cheal own the Creaform VXelements Suite software which allows our team to provide Reverse Engineered CAD models, high resolution mesh models, quality inspection reports, and much more.

FARO VantageS Laser Tracker

- Accuracy (MPE): 16μm + 0.8μm/m

- Point to point accuracy (in-line) up to 0.009 mm

- Point to point accuracy up to 0.022 mm

- Working range up to 80m

Our laser tracker is equipped with an activeSeek technology that allows it to find and follow the target, even after the user passes behind obstructions. With this technology we can survey small, tight, hard to reach areas in a fast and dynamic way.

Metrology Services

- Assembly Alignment

Bearing alignments, rollers alignments, machine train alignment. - Part and Assembly Inspection

Including: dimensional verification, geometric inspections, alignments checks, surface profiling, QC. - Machine Installation and Alignment

This technology alleviates the need to install piano wire to align machinery which is not only a health and

safety hazard, but time consuming and costly on labour.

The Tracker method assures fast and accurate alignments supported with comprehensive reports for QC records provided through the Spatial Analyzer software platform. - Reverse Engineering

To create point clouds, meshes, 3d models to support design, for rapid prototyping, replicas, etc,

This technology is highly used in the automotive and medical industry, in aerospace and for art and sculpture reproduction. - Deformation Monitoring

Our team can set up a network of control nests to periodically monitor specific points or surfaces on structures. The data collected over time is fed to the engineers to analyse how these points move or deform.

Benefits of using Laser Tackers and Handyscanners

- Exceptional Precision

Up to 0.022 mm. - Real-Time Feedback

Allowing for real time adjustments and on-site part quality assessment. - Dynamic Measurements

Making this technology useful for motion analysis. - Fast

Faster compared to traditional tooling. - Safety

No more need for cumbersome measuring tools. Scans completed quickly lessening time spent in confined spaces or hazardous environments.

Cheal provides this service nationwide or internationally if requested.

Contact:

Steve Bowden

M: 027 477 8178 | E: steveb@cheal.co.nz

Laser Trackers and Handyscans: Where Precision Meets Performance.

CREAFORM HANDYSCAN 700

3D laser scanning of a TRV main valve body

FARO VANTAGES LASER TRACKER

Laser tracker target resting in hydroelectric turbine bearing

Cheal team setting out penstock flow meters

Generator bearing alignment

Scanning of parts for reverse engineering.