Laser scanning provides fast, efficient data capture for design and modeling in 3D. With this technology we can collect large amounts of data over complex structures or surfaces in hazardous environments.

Cheal has extensive scanning experience being an early adopter of this technology in 2011 throughout different industries. Our team holds Confined Spaces and Gas Monitoring competencies together with Working at Heights competency. This allows our scanning team to access complex, difficult to measure confined space environments such as tunnels and hydroelectric power plant penstocks, scroll cases, and draft tube environments.

Our terrestrial scanners are typically absolute point accurate to + 2mm.

Laser Scanning Services

- Topographic Surveys

To capture ground levels, topographic features including building, services, signage, road furniture, road corridors, and other complex features to provide for civil engineering design. - Tunneling

Laser scanning can be used in tunneling projects for as-built, monitoring the construction and quality control. - 3D Scanning of Buildings

Scan to BIM. Scanning for structural analysis, for as built, for future designs and remediation works. - 3D Scanning of Pipes & Structures

Pipe capture for 3D modeling, design and refit, or as built records or corrosion mapping. - 3D Scanning of Cultural or Historical Buildings

Provides a comprehensive and accurate means of documenting, analyzing, and preserving historical buildings for future generations. - Erosion and Slope Monitoring Surveys

In hazardous environments, monitoring of coastal erosion, mapping and monitoring of landslides, slips or steep slopes can be carried out safely and quickly. - Deformation Monitoring

To detect possible changes in the shape or structure of objects or surfaces. To support the decision making process.

Benefits of using Laser Scanners

- Safety

Survey of hazardous or inaccessible areas remotely. - Faster and Cost Effective

Scans can be performed in minutes, being a non-invasive methodology, this allows our team to do the work without interfering in our clients’ operations. - Accurate

All our data goes through a robust QA system and our scanners are regularly tested to meet high industry standards. - Unobtrusive

All data can be collected in a single visit – “do it once, do it right”. - Deliverables

Variety of outputs and format files and digital solutions.

Cheal provides this service nationwide or internationally if requested.

Contact:

Steve Bowden

M: 027 477 8178 | E: steveb@cheal.co.nz

Gisela Ripoll

M: 021 195 2642 | E: giselar@cheal.co.nz

Shaping Tomorrow’s World, One Scan at a Time.

Accessing a penstock to carry out laser scanning for corrosion mapping

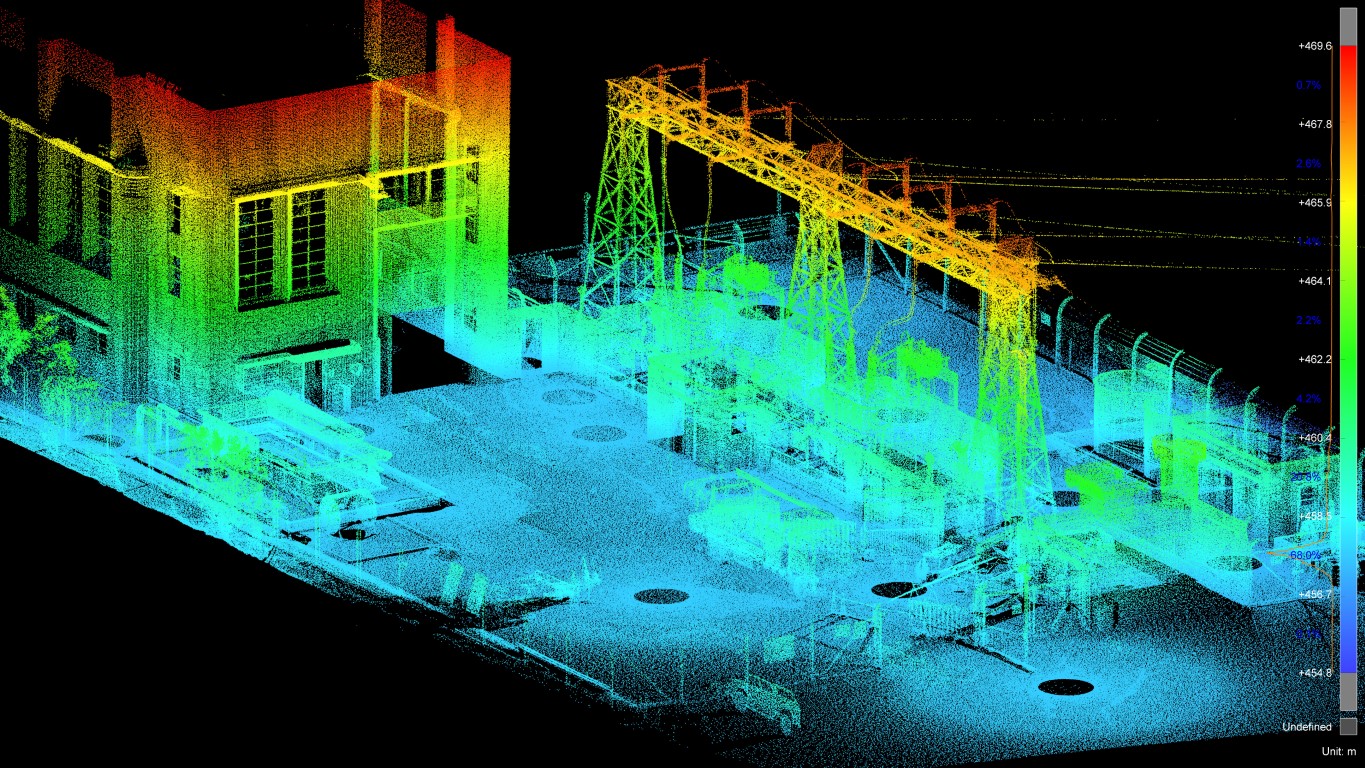

3D point cloud of 3D scanning of a switch yard.

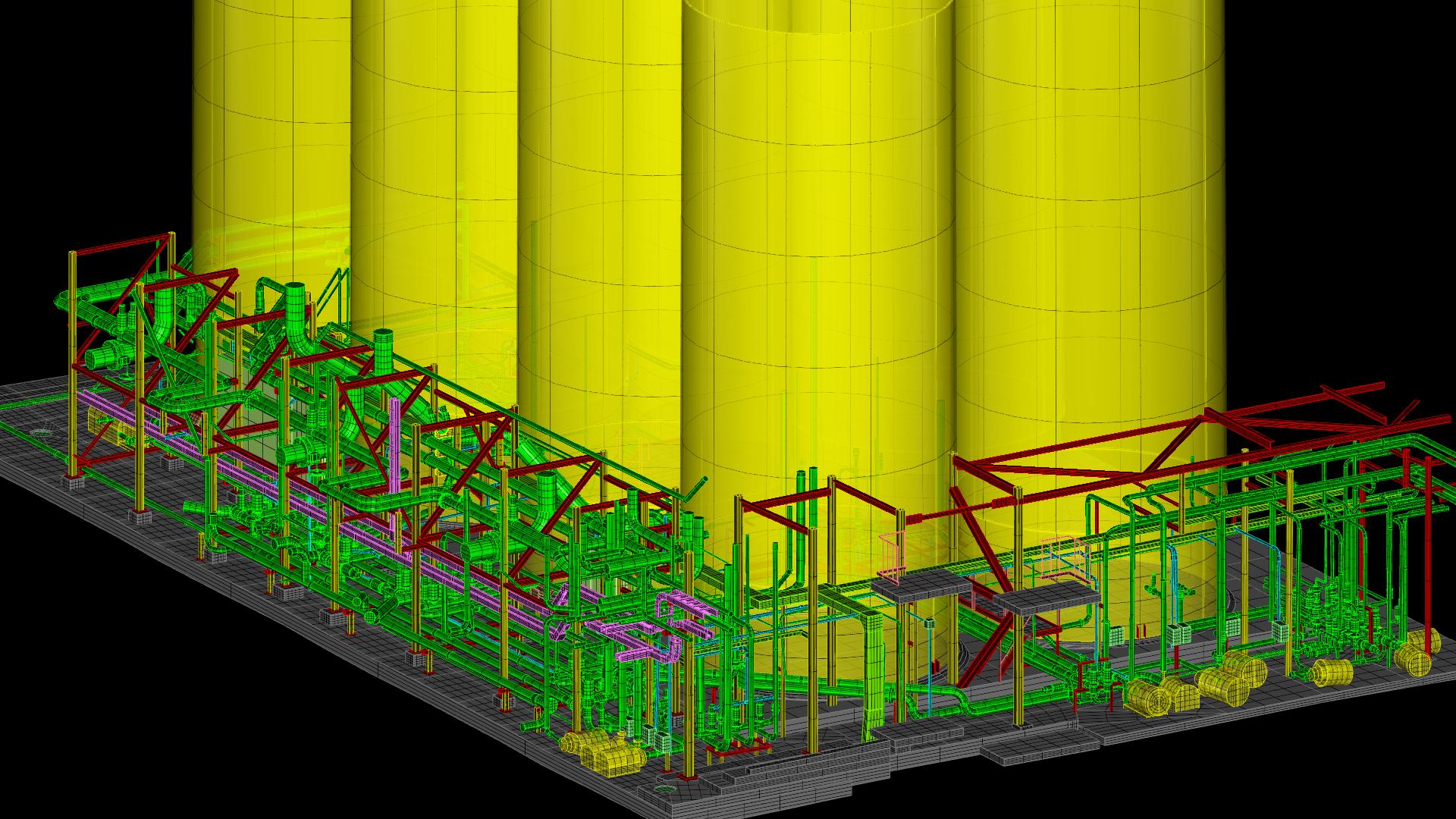

3D model created from a point cloud

3D point cloud captured with out laser scanner.